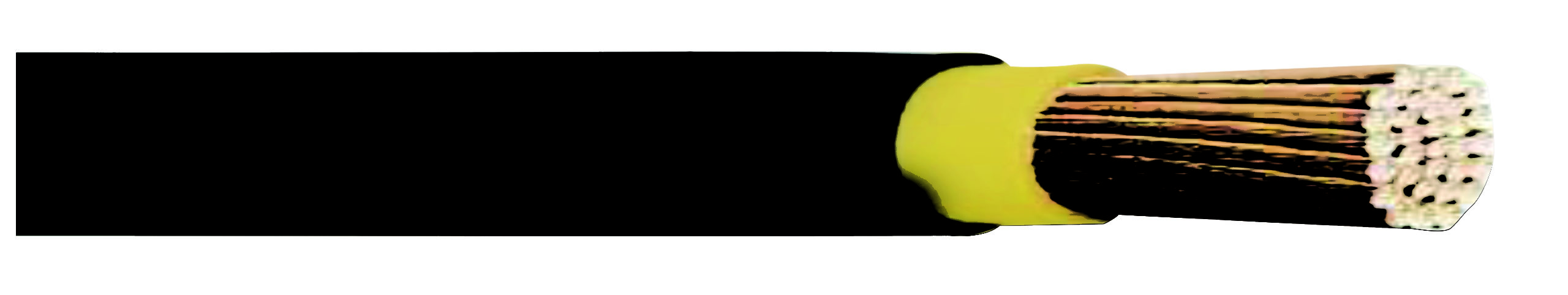

DOUBLE INSULATED COPPER WELDING CABLE – MODEL CWC

Features

- Resistance to oil, solvents and chemicals

- High resistance to cuts, tears & abrasion

- Excellent ozone and weather resistant

- Outstanding toughness

- Durability

| Model | Cross-Sec (Sq.mm) | Radial thickness of sheathing (mm) | Outer Diameter min ~ max (mm) | Max Resistance @20°C (ohm/km) | Current Rating at % Duty Cycle

|

Approx. AWG. No | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CWC35 | 1×35 | 3.5 | 11.7 ~ 13 | 1.16 | 148 | 191 | 270 | 2 | |||

| CWC50 | 1×50 | 4.2 | 13.5 ~ 15 | 0.81 | 199 | 256 | 385 | 1 | |||

| CWC70 | 1×70 | 4.2 | 15.5 ~ 17.2 | 0.66 | 248 | 320 | 452 | 2/0 | |||

| CWC95 | 1×95 | 4.2 | 16.5 ~ 18.5 | 0.43 | 296 | 382 | 540 | 3/0 | |||

| CWC120 | 1×120 | 4.3 | 18.2 ~ 20.5 | 0.35 | 381 | 492 | 697 | 4/0 | |||

Application

- Rubber insulated flexible welding cable are used to connect Welding Machine & for better welding proficiency.

- The robust construction makes these cables resistance to both cold & heat as well as to flames.

- They are suitable for use in open spaces and in dry and damp conditions.

- Copper welding cables produced by weldman are heat resistance and durable.

ALUMINUM WELDING CABLE – MODEL – AWC

Features

- Resistance to oil, solvents and chemicals

- High resistance to cuts, tears & abrasion

- Excellent ozone and weather resistant

- Outstanding toughness

- Durability

- Weldman welding cable has a unique rubber compound technology for better durability.

| Model | Cross-Sec (Sq.mm) | Radial thickness of sheathing (mm) | Outer Diameter min ~ max (mm) | Max Resistance @20°C (ohm/km) | Current Rating at % Duty Cycle

|

Approx. AWG. No | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AWC35 | 1×35 | 2 | 11.1 ~ 13.1 | 0.903 | 176 | 227 | 321 | 2 | |||

| AWC50 | 1×50 | 2.2 | 13.0 ~ 15.0 | 0.641 | 222 | 287 | 405 | 1 | |||

| AWC70 | 1×70 | 2.4 | 15.2 ~ 17.2 | 0.45 | 280 | 361 | 511 | 2/0 | |||

| AWC95 | 1×95 | 2.6 | 17.9 ~ 19.9 | 0.33 | 339 | 438 | 619 | 3/0 | |||

| AWC120 | 1×120 | 2.8 | 19.2 ~ 22.2 | 0.26 | 404 | 522 | 738 | 4/0 | |||

Application

- Rubber insulated flexible welding cable are used to connect Welding Machine & for better welding proficiency.

- Used in Automobile Industries, Shipbuilding, Transport, Steel Plants, Railways, Refineries, Oil fields, Automatic Welding Robots, Construction & Coal Mines.

- Aluminum welding cables are light weight and easy to carry and cost effective

- The robust construction makes these cables resistance to both cold & heat as well as to flames.

- They are suitable for use in open spaces and in dry and damp conditions.